Project Description

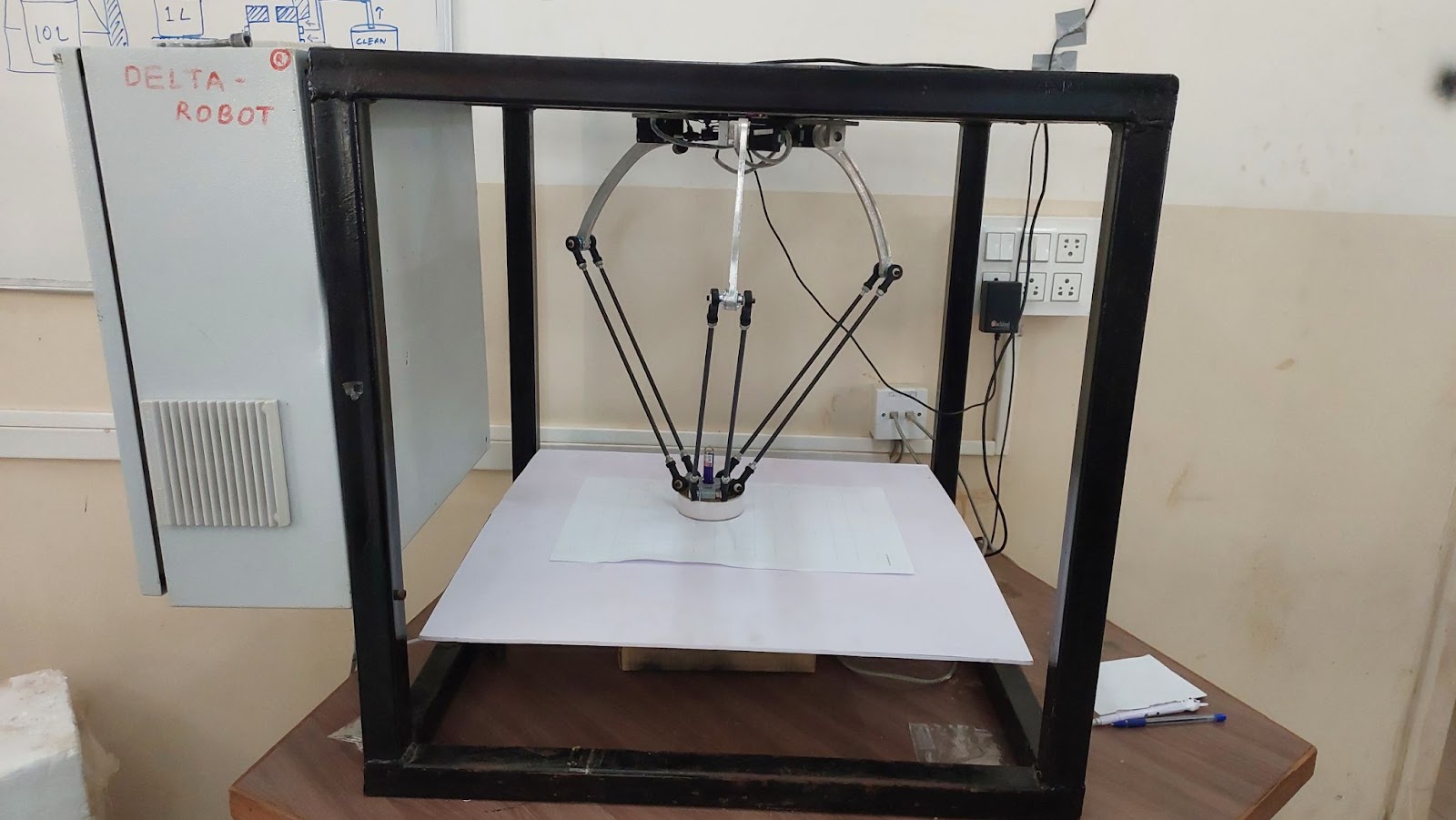

The 4-DOF Delta Robot for Precision Demonstration was developed as a cost-efficient, power-conscious solution to showcase high-accuracy motion control. The robot is designed with maximum repeatability, forming the foundation for future integration into inspection and quality control systems in industrial settings.

The current prototype emphasizes structural accuracy and movement precision. A laser pointer mounted on the end-effector highlights repeatability by pointing at predefined grid points, demonstrating the robot's capability to return to the same positions with minimal deviation.

To enhance usability and verification, a custom-built UI using CustomTkinter allows real-time control of the robot. Additionally, a Simulink-based digital twin mirrors the robot's movement through socket programming, enabling a synchronized physical-virtual testing environment. Both of these systems were developed as part of the core software contributions to this project.

Technologies Used

4-DOF Delta Kinematics, CustomTkinter, Python Sockets, MATLAB Simulink, BLDC Motors, Laser Pointer, Embedded Microcontrollers